No products in the cart.

Quicklime – An Important Component In Steel Production

Day 31/12/2024

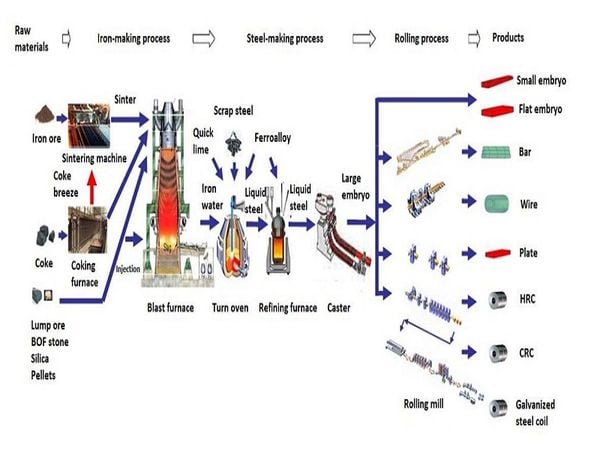

Quicklime is an important component, used in steel production industry since a very long time. The properties of lime, contributing with CaO-molecules, enable the steel plant to have the right basicity in the steel slag during the first metallurgical steps of the steel production process. This property of the slag is important during removal of impurities from the steel, as the right slag property enhances the transfer of the impurities from melt into the slag.

Steel Making

Quicklime, also known as calcium oxide, plays a crucial role in the steel production process. It is an essential component in the manufacture of steel due to its ability to remove impurities and control the temperature of the furnace. This essay will explore the various ways in which quicklime is used in steel production and why it is considered an indispensable material in this industry.

Removal of impurities

One of the primary functions of quicklime in steel production is as a fluxing agent. When quicklime is added to the furnace, it reacts with impurities such as silica, phosphorus, and sulfur present in the iron ore, forming slag. This slag helps to separate the impurities from the molten iron, allowing for cleaner and higher quality steel to be produced. Without the use of quicklime as a fluxing agent, the steel produced would be of inferior quality and not suitable for commercial use.

Steel Processing

Regulate the temperature

In addition to its role as a fluxing agent, quicklime is also used to regulate the temperature of the furnace during the steelmaking process. By adding quicklime to the furnace, the temperature can be increased to the desired level for the proper melting of the iron ore. This temperature control is essential for achieving the right chemical composition and physical properties of the steel being produced. Without quicklime to regulate the temperature, the steelmaking process would be inefficient and lead to inconsistent quality steel.

Desulfurization process

Furthermore, quicklime is also used in the desulfurization process of steel production. Sulfur is a common impurity found in iron ore that can lead to the formation of brittle steel with poor mechanical properties. Quicklime reacts with sulfur to form calcium sulfide, which can then be removed from the steel as slag. This desulfurization process ensures that the steel produced is of high quality and meets the required standards for use in various industries.

Desulfurization process of steel production

Final

In conclusion, quicklime is an essential component in steel production due to its multiple functions as a fluxing agent, temperature regulator, and desulfurizing agent. Without quicklime, the steelmaking process would be inefficient, and the quality of steel produced would be compromised. The use of quicklime in steel production is also a testament to its importance in the industrial sector and highlights the significance of this versatile material in manufacturing high-quality steel products for various applications.

At Viet Nam Technology Mineral JSC, with 10-year experience in manufacturing and exporting Lime products, we commit to supply qualified Quicklime for manufacturing Steel. we work together with our customers to solve problems and define solutions that aid our steel customers to succeed in this highly competitive industry.

Contact us for competitive quotation:

VIET NAM TECHNOLOGY MINERALS JSC – SHC GROUP

Mr. Leon Vu – International Sales Manager

WhatsApp: +84 936 306 698

Email: export5@shcgroup.vn