No products in the cart.

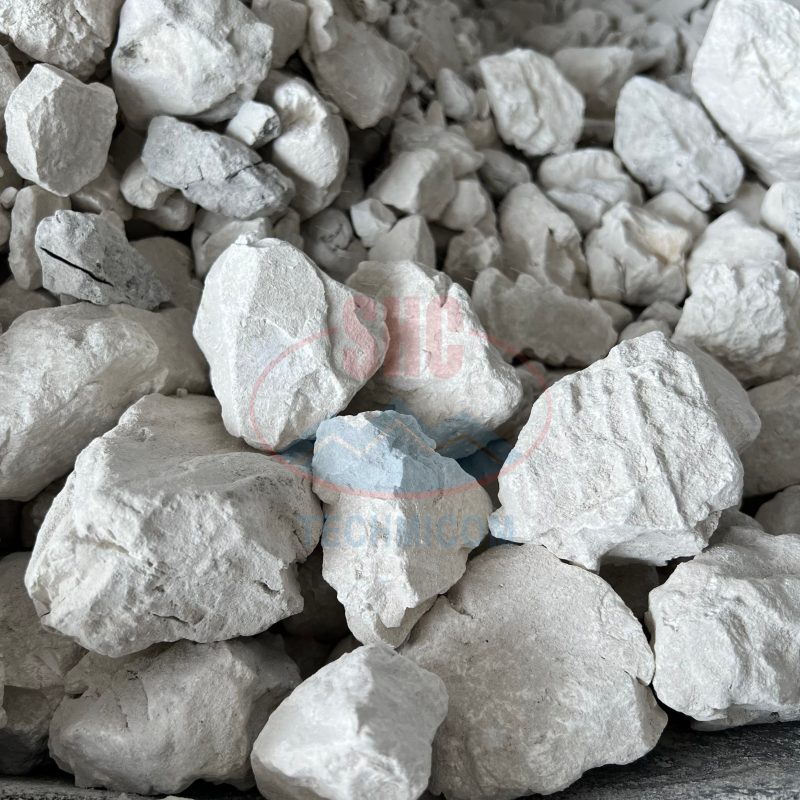

QUICKLIME USING IN MINING INDUSTRY

Day 08/04/2024

Quicklime, also known as calcium oxide, or burnt lime, is a widely used industrial mineral with many applications across various sectors. In the mining industry specifically, calcium oxide plays a crucial role in the processing of ores and minerals. Its key properties of high alkalinity and reactivity make it a valuable asset for mineral separation.

When quicklime, CaO, comes into contact with water, it undergoes hydration and produces heat in an exothermic reaction. This makes calcium hydroxide, also called hydrated lime. The very high pH levels generated make it effective at solubilizing certain components in mineral slurries. In mining operations, it is commonly employed to process sulfide-bearing metallic ores that contain metals such as copper, zinc, lead, and gold.

By raising the pH, quicklime can assist in differential flotation to separate saleable sulfide mineral concentrations from gangue. The alkaline environment helps dissolve and precipitate valuable heavy metal sulfides for easier recovery. It works to solubilize certain sulfides while leaving others intact.

In addition, quicklime plays an important role in neutralizing acidity. In mines, acidic waters can form in drainage systems and tailings impoundments due to oxidation of sulfide minerals exposed to air and moisture. Quicklime effectively neutralizes these acidic conditions and brings the pH to safer levels before release into the environment.

Overall, thanks to its calcium properties and reactivity, quicklime is a workhorse material in mining applications worldwide. Whether processing metal ores or managing drainage waters, calcium oxide in the quicklime form is a mainstay in bringing efficiency and environmental responsibility to industrial mineral extraction.

__________________________________________

Contact us for competitive quotation:

VIET NAM TECHNOLOGY MINERALS JSC – SHC GROUP

Mr. Leon Vu – Sales Executive

WhatsApp: +84 936 306 698

Email: export5@shcgroup.vn