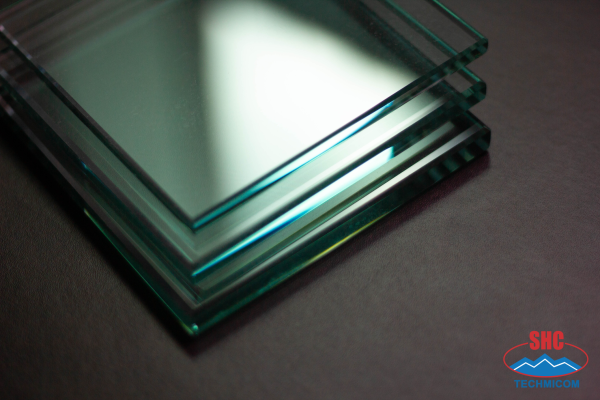

DOLOMITE IN FLOAT GLASS MANUFACTURING

Dolomite, a mineral composed primarily of calcium magnesium carbonate, plays a crucial role in the manufacturing of float glass, making it an essential component in the production process.

Dolomite (CaCO3.MgCO3 – Calcium Magnesium Carbonate) – TECHMICOM

Dolomite, a mineral composed of calcium magnesium carbonate, plays a crucial role in the manufacturing of float glass. This high-grade limestone has three key roles in the float glass production process that contribute to the quality and functionality of the end product.

✅Flux material: This means that it lowers the melting point of the glass mixture, allowing for a more efficient melting process. Its high melting point, is advantageous for maintaining high temperatures during glass production. Additionally, dolomite has a low iron content, reducing the risk of unwanted coloration or impurities in the glass. By acting as flux material, dolomite helps to initiate the fusion of the other ingredients required for the glass mixture.

✅A stabilizer: Dolomite contains a balanced mix of calcium and magnesium, which helps to prevent devitrification. Devitrification is a phenomenon where the glass spontaneously crystallizes during cooling, leading to a loss of transparency and strength. Dolomite’s stabilizing effect ensures that the glass mixture remains homogeneous and doesn’t undergo any undesirable crystallization. Its chemical balance helps maintain the integrity of the overall composition, contributing to a higher quality end product.

✅ Determining the physical properties of the float glass: The addition of dolomite to the glass mixture enhances its strength, making it more resistant to breaking or cracking. This is crucial, as float glass is often utilized in applications where durability is paramount, such as architectural and automotive glass. Additionally, it improves the glass’s clarity by reducing the presence of impurities and enhancing the light transmission properties.

Dolomite for Float Glass Manufacturing

In conclusion, dolomite’s significance in float glass manufacturing cannot be overstated. Its roles to physical properties are vital for ensuring a high-quality end product. As a flux material, dolomite aids in the efficient melting of other raw materials, while its stabilizing effect prevents devitrification. Additionally, dolomite enhances the glass’s physical attributes, including strength, clarity, and resistance to thermal shock. The diverse functions of dolomite make it an indispensable ingredient in the float glass production process.

Contact us for competitive quotation:

VIET NAM TECHNOLOGY MINERALS JSC – SHC GROUP

Mr. Leon Vu – Sales Executive

WhatsApp: +84 936 306 698

Email: export5@shcgroup.vn